Zirconium corundum / Zirconia fused alumina

Zirconium corundum has good melt erosion resistance, as a kind of advanced abrasive, can manufacture high-performance heavy load grinding wheel, and has a good grinding effect on steel, cast iron, heat-resistant steel, and various alloy materials; In addition, zirconium corundum is also a high-grade refractory raw material, is the ideal material for making high-performance sliding nozzle and immersion nozzle, and can also be used to make zirconium corundum bricks for glass melting kiln.

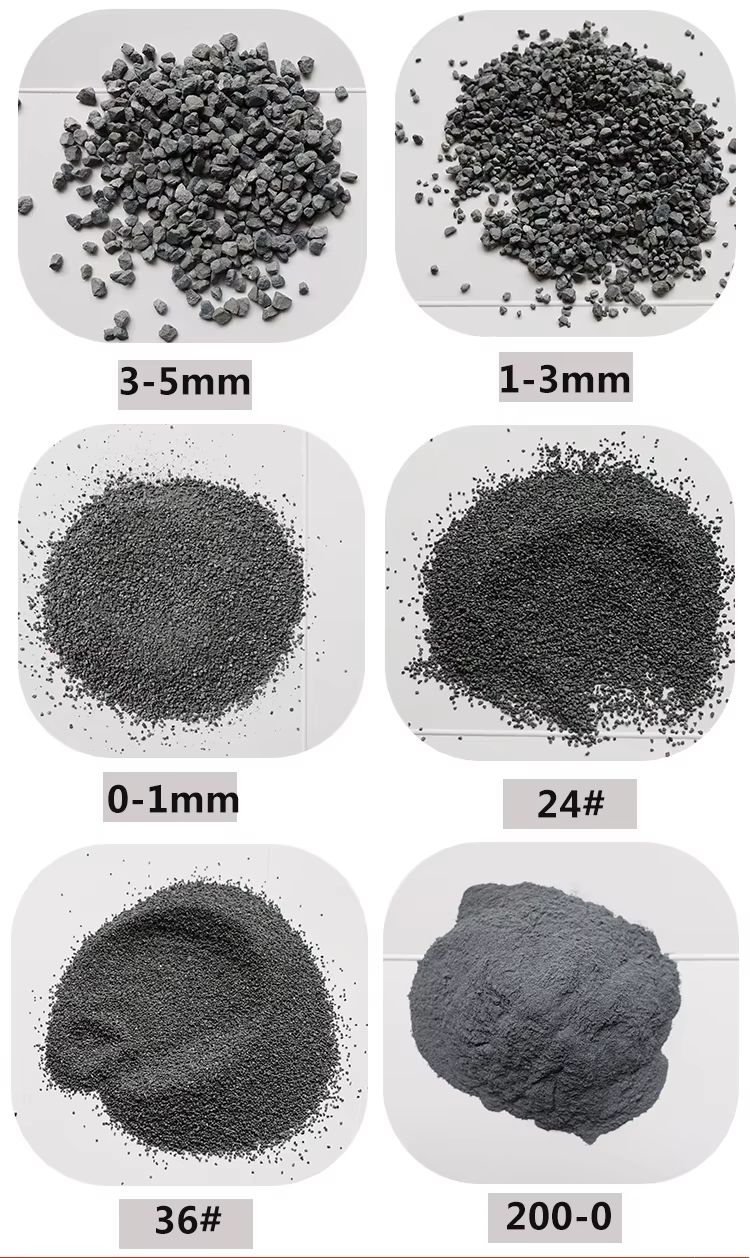

- Commodity name: Zirconium corundum / Zirconia fused alumina

Classification:

Key words:

- Product Description

-

Zirconium corundum is alumina, zirconium oxide as raw materials in the arc furnace by high temperature smelting above 2000℃, is containing 10%-40% zirconium dioxide (zro2) corundum.

Zirconium corundum has tough texture, dense structure, high strength and good thermal stability.The main mineral phase of zirconium corundum is a eutectic formed by A-al2o3 and Al2O3-ZrO2, the subcrystalline phase is plagiozircon, there is also a small amount of glass phase, according to the content of ZrO2, generally 25 zirconium corundum (ZrO225%) and 40 zirconium (ZrO2 40%).

High strength wear-resistant plastic is a clay billet or mud mass amorphous refractory material constructed by ramming, vibration or pressing method, and a certain grade of refractory aggregate, powder, binder, admixture with water or other liquids is fully mixed. High strength wear-resistant plastic is made of wear-resistant raw material as aggregate, powder or liquid binder combined with a number of additives, which has good wear-resistant property at high temperature.